How much does it cost to design a clothing line?

To develop a product the average costs ranges from $18,000-$25,000+ per product, depending on complexity of the products this cost can vary. These numbers are broad averages.

If I'm not located in Minnesota can I still work with you?

Absolutely! Over 80% of our clients are NOT from our beautiful (and sometimes cold) state of MN. We have the process down pat, where working with brands remotely is a breeze. Some of our brands fly in to meet us, but some we only ever meet over video. What ever works for you!

Should I attend The Apparel Academy?

Uh, shya! If you want to understand how to be the best apparel entrepreneur you can be, this is the best way. We teach an overview of the Clothier 4 Step Process and how, as the brand owner, you can contribute to the success of your products. We recommend that all of our clients attend The Apparel Academy. It is the perfect building block for anyone who is new to the fashion/apparel industry.

What is your MOQ for Production? (Minimum Order Quantity)

We have a 1000 piece per style minimum. Yes, you can mix colors and sizes in there.

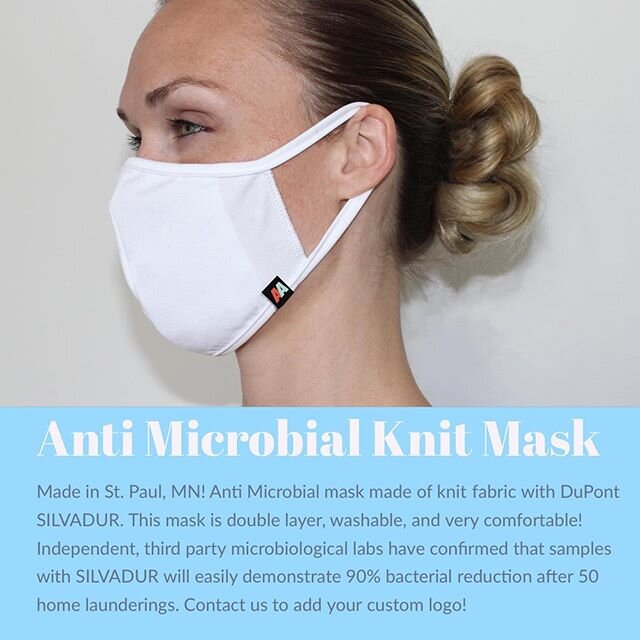

What type of products does Clothier Design Source Produce?

We are great at activewear, high stretch, functional, medical, children's, outdoor wear and most clothing with a purpose.

For the entire process it is 6-9 months. For just production (after your product is developed in steps 1-3) it is 6-10 weeks.

What are your lead times?

What's your process like?

You will be assigned a Design Manager who is your mentor and your guide in the entire process. We follow The Clothier 4 Step Process of 1.Design, 2.Prototype, 3.Tech Design, 4. Manufacture. For each step of the way you work together with your Design Manager and you approve everything before we move on to the next step. This keeps everyone on the same page and your Design Manager is using their expertise in apparel development to make suggestions and improvements.

Can we make a custom fabric?

Why yes we can! The sky is the limit for fabrics. We work with over 250 fabric mills around the world that we have developed relationships with. We can get it done.

Why should I manufacture in the US and not overseas?

After you factor in the cost of headaches, time loss, shipping costs, mistakes and poor quality, your bottom line can be pretty similar to manufacturing in the USA. The per piece price is higher in the USA but it is those hidden costs that start to add up and in the end the advantage is clear. By making in the USA your team can communicate with you real time, they can problem solve and we can offer smaller quantities.

Are my ideas confidential?

Absolutely. We will happily sign a non-disclosure upon request. We have one we can provide upon request also. All employees are reminded in our quarterly meetings how crucial the clients confidentiality is to our success. Without us doing a great job on this front we would not still be here.