Before your clothes roll off the production line, there are some things that you need to know. I've compiled this eight-point checklist that will improve your chances of manufacturing success.

1. CREATE A TECH PACK

First, you need to create a tech pack — it's a roadmap for manufacturing your clothing line. This sheet will include things like measurements, materials, and sizes. You will send your tech pack to your manufacturer so they know how to make your product according to your exact specifications.

2. ORDER CARE LABELS

Care labels are really important. They include valuable information about your clothing — the size of your garment, the country of origin, washing instructions, etc. Here in the United States, care labeling is a legal requirement — the Federal Trade Commission has clear guidelines on what you should include on your label — so make sure you get it right.

Labels can take up to eight weeks to receive, so order them early on in the manufacturing process.

3. CREATE COLORWAYS

Colorway layouts serve as a blueprint for manufacturers when they make your clothes. You need to submit these to your manufacturer and have them approved.

Colorways tell manufacturers the exact colors to use when producing your garments.

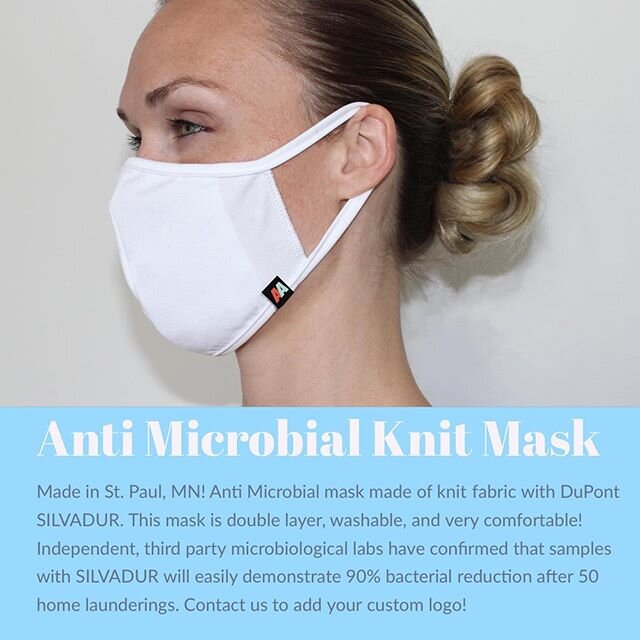

4. TEST FABRICS

Test your fabrics before you send them to your manufacturer. Once you're happy with the results, order the amount you need. This can take between 2-6 weeks (4-10 weeks for custom orders), so you need to act fast.

5. TEST YOUR TRIMS

You also need to test your trims before you can manufacture clothes. Order times are similar to fabrics: 2-6 weeks or 4-10 weeks for custom orders.

6. APPROVE THE FINAL SAMPLE

This is the most important point on this list. The problem is, designers often forget to do this, which causes a lot of problems.

Once your manufacturer has sent you a final sample. You need to test and approve it. Check that it meets your requirements and brief. If it doesn't, you need to ask your manufacturer to make changes.

7. APPROVE THE FINAL PATTERNS

Once you have approved the final sample, you need to check the final patterns. Don't just focus on one size — you need to approve garments in every size you plan to sell. If there are problems, talk to your manufacturer.

8. CREATE A PURCHASE ORDER

By now, you should be good to go. But there is one final step: Creating a purchase order. Your purchase order is a document that lists your product quantities and agreed prices, and you will need to send this to your clothing manufacturer.

Follow the eight steps on this list if you want to streamline the apparel manufacturing process and get your garments to market in a quicker time frame. Ready to manufacture your clothing line? Download our checklist and find out!

Want to learn more about the clothing industry? The Apparel Academy provides you with the skills you need if you are trying to understand the business side of fashion. Click here to find out more.